Kanban, eKanban and Scrum

Imagine a scenario where you are traveling or on your holidays and your subordinates are updating and putting live record of everything including production sequence, ongoing plans, finished projects and products, livestock records…and almost everything including their communication details.

Imagine yourself checking your IOS device and observing the bottleneck and seeing people immediately putting actions on it. You are getting every report of analysis if you want to dig it further…You are getting a daily, monthly and a yearly update of nearly everything (with graphs and statistics!). Further, the software is automatically listing those works in order of priority first! Think of a management tool that is showing you potential wastes and risks involved in going another way around.

What if I further tell you that you can learn to manage, control and keep a live observation of all the activities of your project for free? And that too…in an updated version in your mobile devices? Not to mention you can get more cool features in an updated and paid version.

And the best part is you can use the tool for your personal purpose too to track a record of your planned, ongoing and finished works keeping a timeline and a pull system.

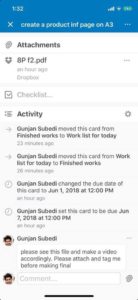

Don’t believe me? Here is my mobile screenshot of e-Kanban which I operate through IOS:

kanban board on mobile

And what if I told you that this is a secret that helped me learn few things in leisure managing a long day demanding job at a Japanese lab at the same time? But miles before jumping into the e-kanban system you have to be in touch with Kanban and Scrum which are slightly different in nature:

Kanban (看板) (This is Kanji for signboard in Japanese)

The story of Kanban in Toyota

The management and production requirements in Toyota was very huge and it couldn’t rely just on the salesman to restock, say, coupes.

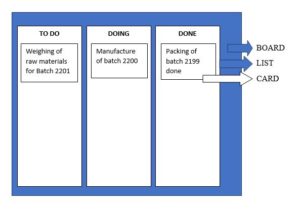

Taiichi Ohno developed Boards, lists, and cards for this purpose-

- Boardscontain or encapsulate a project or a workflow.

- Listscontain and often prioritize cards that share a similar status or attribute.

- Cardsdescribe the task, including related or supporting information

First developed by Taiichi Ohno (Industrial Engineer at Toyota), Kanban is a scheduling system for lean manufacturing and projects requiring just-in-time manufacturing (JIT).

Toyota has formulated six rules for the application of Kanban:

- Each process sends requests (kanban) for the supplies that it needs to its supplying processes.

- Each process produces according to the quantity and sequence of incoming requests.

- No items are made or transported without a request.

- The request associated with an item is always attached to it.

- Processes must not send out defective items, to ensure that the finished products will be defect-free.

- Limiting the number of pending requests makes the process more sensitive and reveals inefficiencies.

kanban board

conditions, i.e., TO DO, DOING AND DONE. After work finishes the cards automatically are shifted to the right. The priority of the work can be determined by placing the card on the top or putting a speed score or putting the card of the necessary color log so that it can be very easy to understand the whole work just by viewing. The card can also be further modified by adding details such as whom the work is assigned to/ what date and time and what is the duration of the work. This all is basically easily possible through the electronic Kanban system that will be shortly described afterward.

Workflow on Kanban

Typically for the business, the Kanban board and contents can further be divided into the following subheadings:

- Backlogitems that are being brainstormed or that are not yet ready to have work done.

- Tasksthat are ready to be worked on. The highest priority task should be at the top of the list.

- In progressis where cards go once work has begun.

- In reviewis the stage when tasks are reviewed, approved, or sent back to “in progress” for more work.

- Doneis the status of cards when the work is completed, but the task, such as a Pandora campaign, has not yet run.

To learn more about Kanban, eKanban, Scrum and other related free contents, lean six sigma and business improvement templates, free certification e-courses, ebooks and monthly newsletters by clicking here

Benefits of a Kanban Inventory System

Reduction of Costs: Excess inventory costs a lot of money. Sometimes much from our pocket goes to buy excess inventory that has no use. Stocking the right amount of inventory definitely saves you time and money.

Reduce Inventory Levels: The Kanban system visualizes every loophole of the problems in manufacturing and business. It helps to visualize where is the bottleneck of the problem that is causing the pile of stock in the production or business processes. If a company over-produces inventory, it often sits in a stockroom for long periods of time, and companies have to decide what to do with the excess (sell, give away, or discard). Additionally, when the stock isn’t touched immediately, it can be difficult to determine if there are damaged units.

Reduce time: Our practical findings have shown that a Kanban system is able to reduce up to 25% of the production and process time. A key to this was the fact that the Kanban system focuses on the problem to every staff and managers. When the focus is more on the potential item causing more problems, there is a tendency to solve that problem quickly and thus reduce the problem.

No Storage in the Production Area: In Kanban, parts are only delivered to the production line when needed. This space savings provides ample room on the production line for workers to assemble the product.

Provides Managers Progress Reports: A recent system called e-Kanban is becoming very popular these days. Powerful Kanban Software can provide the daily reports of the activities and help managers in organizing and improving the work process.

Prevents Overproduction: When you know what you are producing, in what quantity, what is the need and where is your work is heading, you can easily prevent overproduction.

Flow visualization in a perfect manner: The Kanban board offers a lucid view of the work that is currently going on. Visualization of the flow ensures fast-tracking and planning. In fact, by visualizing the work, you can understand the manner in which it is proceeding so that if changes are required, the proper and timely decision can be taken.

The capability of altering priorities: Rightly as described before, if you need to implement an urgent request, or have a very significant user story, you can simply place it on the top of the queue. The priority of the work can be determined by placing the card on the top or putting a speed score or putting the card of the necessary color log so that it can be very easy to understand the whole work just by viewing.

Things to consider before Jumping into following Kanban:

- If your output is a single piece or batch (or lot) production in a year or very few batches you probably do not need to worry about implementing Kanban. Kanban works best on a continuous production system (need not be the production of the same product or similar batch).

- Prepare an SOP or a meeting what color codes you want to use if the Kanban system you are using is not an e-Kanban. If this is done, the Kanban initiative becomes optimally visible to everybody within the organization at the time of launching.

- Include all the members of the company or at least the key members of the Kanban system. Also, it is very important to maintain the organization chart, job description, training etc., before implementing the Kanban system.

- To implement Kanban, you need to have the support of reliable equipment. So, apply Kanbans in internal areas where you already have TPM or Total Productive Management.

- Kanbans are not permanent and might call for experimentation. Initially, you must be prepared to make adjustments to alterations in sales levels or other enhancement initiatives to bring down the requisite number of Kanban cards or containers.

Scrum

Another possible idea for how you can manage the business or industrial functions is by using Scrum.

Though it is a widely accepted tool in managing software development, why not make it a try to make our management functions easier?

In software development, it is principally used as an agile (collaborative actions over time).

Several software developers make a plan for 2 weeks to 1 month to complete a project (called sprints) and discuss daily in a 15-minute standup meeting sessions (called daily crumbs).

To understand using scrum in our management functions, we have to understand how scrum is used in software development. The scrum project basically consists of a team of 3 kinds of people, product owner (who speaks on the business level giving emphasis to voice of the customer, development team(who actually develop the product) and scrum master (who though named as a master actually works as a facilitator-guiding the development team, conducting daily scrum meetings, keeping a log of all the ideas and resources and motivating the team).

The workflow though may look too complicated in actual scrum applying organizations, is simple. First of all the goal is made for a particular time called sprint planning. The time in which the goal is to be achieved is planned called Scrum which is 2 weeks(generally to at most 1 month).

Then from the backlog (which are a list if all the works), the scrum members select which works they want to complete during that duration and also list out the resources they need to complete those works. When there are many works to be completed, usually the scrum members vote for this which I think could be improved by making a Pareto decision.

After selection of the work or project to be completed in the sprint, a daily scrum is carried out for the entire length of the scrum usually (15 minutes per day at most). This is generally done to understand what bottlenecks are there in a project and what are the risks involved.

When such problem arises a person is designated to work for a solution or the possible solutions are discussed during another meeting (separate and elaborative) if the problem could largely hinder the project. The product is developed and those projects which do not seem to be completed are sent to the backlog again and focus is given in completion of other projects. At the end of the sprint (2 weeks to 1 month allocated time period), the works that are completed are reviewed and discussion for what could be planned for next scrum session is discussed. This meeting is a little longer than a daily scrum meeting.

The product backlog that is to be selected for the next scrum should be organized by the order of the importance so that while selecting the project from the project list, only the most valuable tasks are chosen.

| SCRUM | KANBAN | |

| Project length | Regularly fixed-length sprints (ie, 2 weeks) | Continuous flow |

| Release methodology | At the end of each sprint if approved by the product owner | Continuous delivery or at the team’s discretion |

| Roles | Product owner, scrum master, the development team | No existing roles. Some teams enlist the help of an agile coach. |

| Key metrics | Velocity | Cycle time |

| Change philosophy | Teams should strive to not make changes to the sprint forecast during the sprint. Doing so compromises learning around estimation. | Change can happen at any time |

Back to e-Management again….

- Some of the best e-management tools that I have come across are:

- Breeze- good for managing projects of many clients

- Weaken- Open source

- Trello- Though it has a disadvantage of good services in the paid

- Leankit- Good for lean projects!

Want to learn more about Kaizen and Kanban use in business and services operation and improvement?

Click here to get a Kaizen (continuous business improvement) Facilitator Certification Course